Conformal Coating Job Work

Complete solution to wide range of Conformal Coating process needs such as Operating Conformal Coating Machine, Application of Coating, UV Optical Inspection, Coating Touch-up, Drying / Curing, Coating Thickness Testing, Coating Removal & Reworking & Final Inspection.

EMS has been associated with Lackwerke Peters since 2011 and has acquired expertise in the field of Conformal Coating Application process.

As a one stop solution, based on client’s needs, our experts can assess your requirements and suggest you appropriate solutions.We undertake Conformal Coating Jobwork projects, handling complete process with the help of well qualified and trained team.

Top major companies are our satisfied customers where our team of over 30 B.Tech graduate engineers, trained by Technical team from Lackwerke Peters are working on site.

-

Application of Conformal Coating

Based on client needs offering all major types of Conformal Coating application processes we offer coating through Brush application, Pneumatic Spray Gun, Dip Coating (Manual / Semi-Automated / Automated), Automatic Selective Coating Equipment..

-

UV Optical Inspection

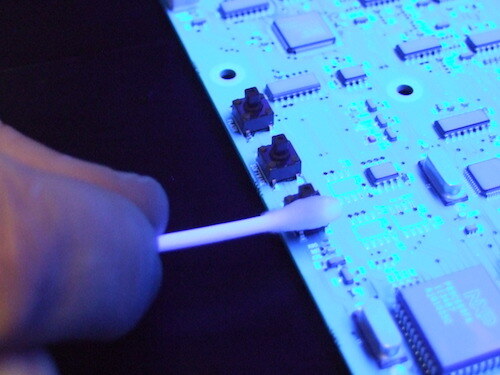

Optical inspection under UV Light to determine uniformity of coating, and detect Anomalies / Defects such as Homogeneity of coating / Absence of Coating on PCB, Air Bubbles, Fish Holes, Uneven Coating surface etc., which can be detected through UV Optical Inspection.

-

Conformal Coating Touch-up

Post UV Optical inspections uneven coating surfaces, left over areas or edges of the PCB Coating area can be recoated with brush coating application or for Reworked PCB boards recoating or touch-ups are required.

-

Drying / Curing of Conformal Coating

Based on the Coatings used and as per Coating manufacturers specifications Curing is carried out. Different types of Curing processes such as Physical Drying, Thermal Curing, Oxidative Curing, Twin Cure (UV + Moisture Curing) are handled by our expert team.

-

Conformal Coating Thickness Testing is carried out through various methods such as

Wet Film Gauge, Eddy Current Probe, & Ultrasonic Thickness Gauge.

-

Conformal Coating Removal & Reworking

Conformal Coating Removal & Reworking is carried out for various reasons, and as per process specified based on Conformal Coating used. The process includes Conformal Coating Removal – based on coating used either with Thinner / Solvents or through Mechanical removal / Sand Blasting / Peeling / Scrapping Post reworking Reapply Conformal Coating / Touch-up, Curing of the Conformal Coating & Optical Inspection is followed.

-

Final Inspection of the Coatings includes

Final Inspection includes Identify / detect any defects or anomalies in coatings (de-wetting, peeling, wrinkles, cracks, fisheyes, orange peel etc,), Uniformity / Homogeneity of coating ensuring no Embedded/entrapped foreign material or Discolouration or loss of transparency, ensuring Completely cured coating layer and that Coating is applied only in the required area.